At Cyclone Technology, we are dedicated to providing innovative cleaning and recovery solutions for various industries. With cutting-edge technology and specialized equipment, we offer efficient, eco-friendly services that deliver exceptional results.

Our leadership team at Cyclone Technology is composed of experienced professionals who are passionate about driving innovation and achieving excellence in everything we do.

Cyclone redefines surface cleaning with cutting-edge technology that’s as practical as it is

powerful.

Cyclone Technology was founded in the ’90s in Tempe, Arizona when Richard Rohrbacher invented the Cyclone head. This revolutionary cleaning marvel utilized wind force for water recovery, eliminating the need for noisy and costly vacuum components. Soon, airports, colleges, event centers and amusement parks were clamoring to purchase the hard surface cleaning machines for themselves.

In 2003, Cyclone Technology was created to manufacture and sell these hard surface cleaning machines. Then, in 2009, the first ultra-high-pressure rubber and paint remover was delivered and sold.

Today, Cyclone stands as the global leader in high-performance hard surface cleaning and paint and rubber removal equipment and services. Over the years, we’ve evolved and innovated, becoming a trusted solution for motorsports, airfields, cities, the military, campuses, and various industrial applications.

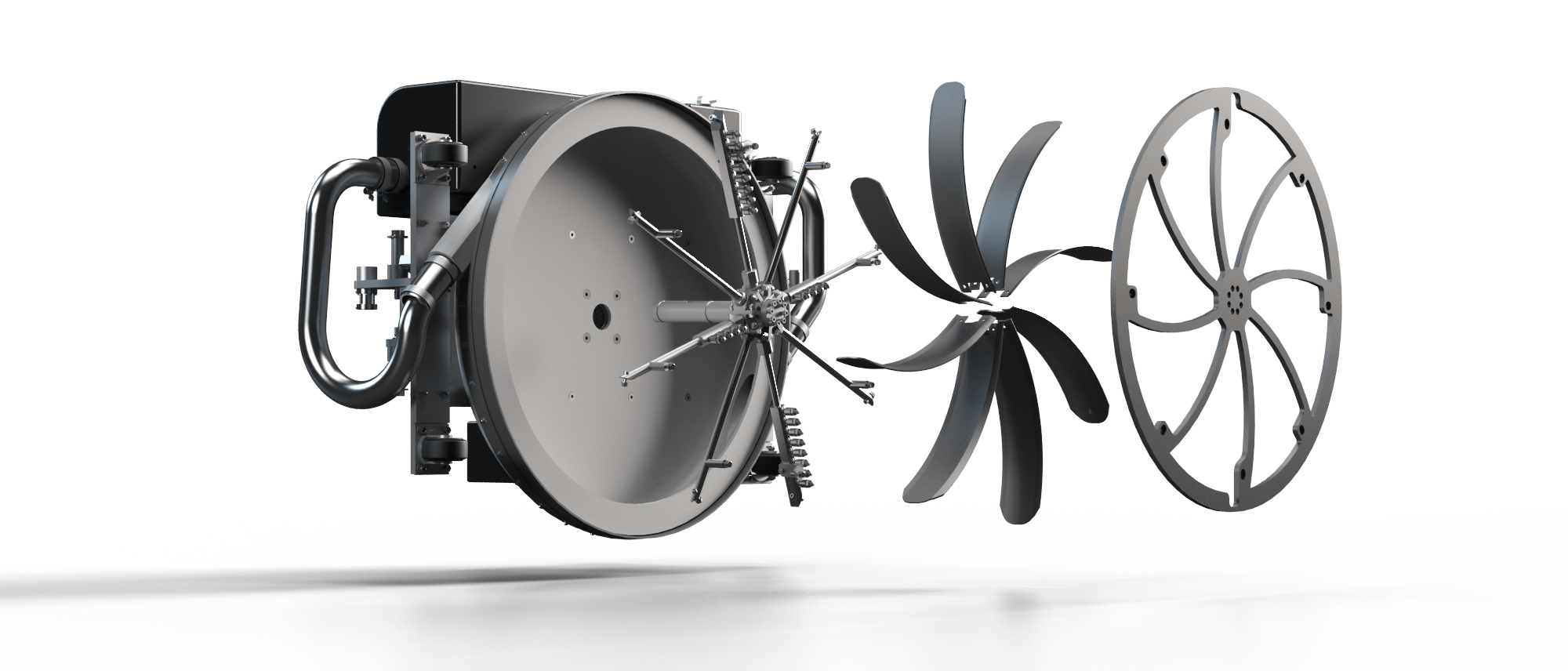

The Cyclone head uses rotating blades to create a powerful axial airflow, effortlessly lifting water, wastewater, and debris from the cleaning surface. Acting like a centrifugal pump, it propels the refuse into a diffuser tank, where air is vented, and wastewater and debris are channeled to a return pump for delivery to an open recovery tank—streamlined and effective.

With its evenly distributed vacuum and low airflow design, the Cyclone head recovers debris using significantly less power than traditional vacuum systems. This efficiency translates to lower operating costs and quieter performance, making it a smarter, more sustainable choice for surface cleaning.

Ultra High-Pressure (UHP) Machines: Featuring two-stage filtration down to 0.35 microns—far exceeding manufacturer standards—Cyclone maximizes the lifespan of pumps, unions, and nozzles. ● Low-Pressure Equipment (CY5500): A proprietary recovery tank removes large debris, followed by durable, cleanable 75- and 30-micron filters that last the machine’s lifetime.

The Cyclone head’s evenly distributed vacuum ensures a thorough, consistent clean across the entire surface—unlike traditional vacuum systems, which lose suction away from their ports. The result is a flawless finish, every time.

Equipped with hydraulically driven pumps, Cyclone machines let you adjust water pressure and cleaning speed on the fly—no nozzle changes required. Choose from preset modes or manually dial in settings to match any job, delivering unmatched flexibility and control.

Unlike vacuum systems that rely on complex, sealed tanks and frequent maintenance, Cyclone’s innovative design eliminates the need for a vacuum pump. Debris flows directly to an open recovery tank, reducing costs, simplifying upkeep, and ensuring quieter, more reliable operation.