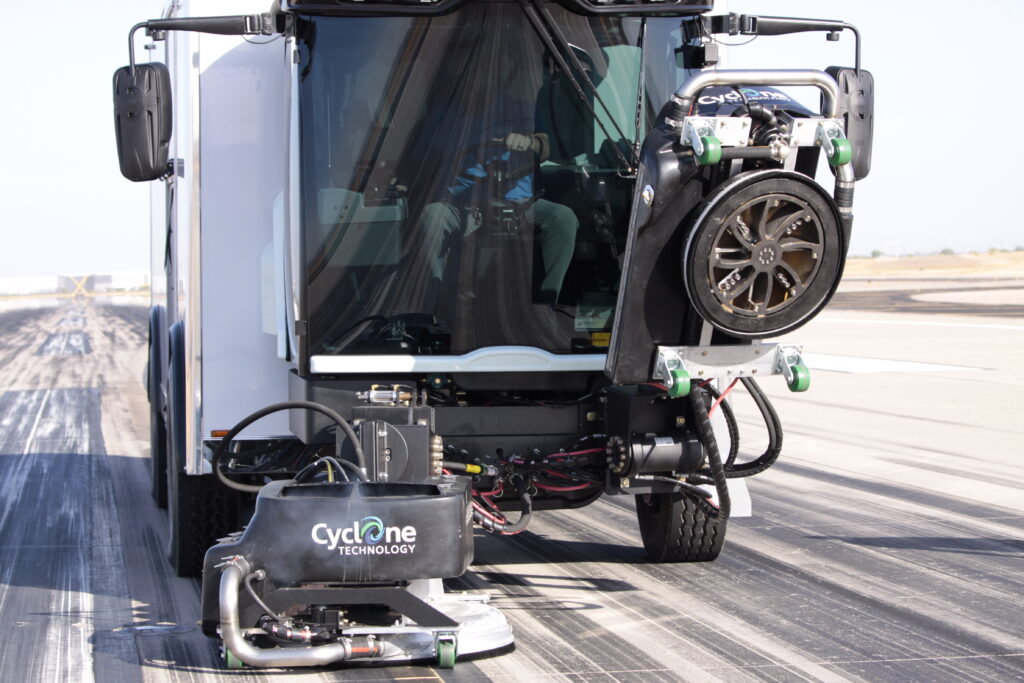

The 4006AC is a specially designed machine that eliminates the need for a costly truck chassis, making it more cost-effective than similar solutions of the same size. Its adjustable output pressure enables quick cleaning of center lines and easy restoration of reflectivity, significantly reducing paint costs. The paint and rubber heads are permanently attached, allowing for easy switching from paint to rubber removal in just minutes.

The 4006AC offers unmatched efficiency and performance, delivering superior cleaning results with advanced technology, making it the ideal solution for any cleanup task.

A specialized container that separates solids from liquids in the collected wastewater where water mixed with debris, grease, and grime is collected. This enables the cleaner water to be either recycled back into the system or disposed of more easily.

Water pressure and cleaning speed can be easily adjusted from the operator’s seat, allowing for precise control and efficient cleaning on any surface.

The powerful and consistent Cyclone head delivers efficient and even cleaning, ensuring every surface is treated with precision. This reliable cleaning performance

The easy to use operating interface allows doe safe and accurate control of the cleaning system.

The 4006AC combines power, precision, and versatility, ensuring fast and effective cleaning across various surfaces while maintaining safety and sustainability for every project.

A vortex of air and pressurized, heated water is controlled from the operator’s seat, allowing maximum results on a variety of surfaces – concrete, asphalt, cobblestone, athletic running tracks and more.